East Parcel Viaduct Removal, Sleepy Hollow, New York

A Creative, Collaborative Approach Eases Bridge Demo at Half the Cost

The East Parcel Viaduct Removal Project is an integral part of the redevelopment of General Motors’ former North Tarrytown assembly plant site in the Village of Sleepy Hollow in Westchester County, N.Y. The multiyear, high-profile revitalization of the area that sits on the shores of the Hudson River includes the construction of residential housing, retail and hospitality—along with the much needed reconfiguration of existing infrastructure.

Recently, the 16,000-sq-ft East Parcel bridge, originally used as a way to transport newly built cars from the assembly plant to a railroad staging area, took center stage, challenging demolition engineers and crews to find a safe and effective demolition strategy on a project with significant logistical limits.

For Sessler Wrecking, the award of this project as the general contractor underscores the company’s willingness to look beyond conventional thinking to meet complex and unusual project

requirements.

Boxed In, Limited Access

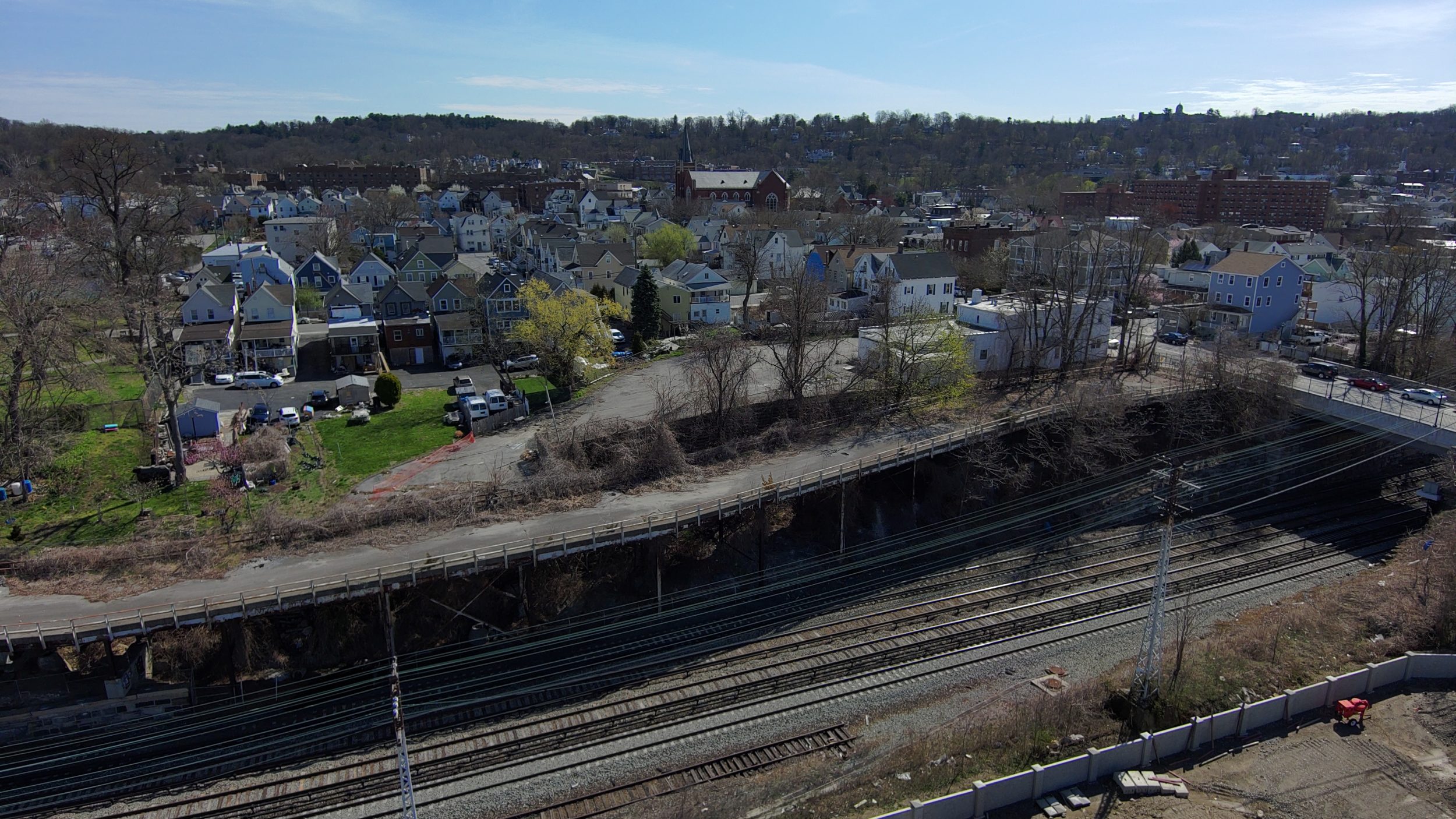

The challenges associated with the removal of the East Parcel Viaduct were largely due to location. The severely deteriorated bridge deck was cantilevered over the very active Metro-North Railroad’s Hudson Line’s four-track third rail with limited access.

Mike Karsten, director of bridge demolition at Sessler Wrecking, explains, “One side of the bridge is located along a heavily sloped area with a decrepit retaining wall and on the other side are the active rail tracks.”

The proposed demolition sequence suggested the structure be lifted in sections to a laydown area using large cranes from a considerable distance away. Sessler recognized this approach

could expose high crane costs due to the tight railroad window. To minimize the total project cost, Sessler Wrecking engineers developed a plan to shore up the bridge and then use smaller excavators to remove the bridge in pieces. The engineered shored-up approach would greatly reduce the costs, shorten the timeline for demolition and would work well in the required—very short—work window.

Because the Hudson Line is one of the main sources of commuter traffic to New York City, Metro-North Railroad required that all work on the bridge demolition, which impacted active rail traffic, occurred during low-volume operational hours—2:00-5:00 a.m.

Once the customized demolition engineering sequence was finalized, Sessler Wrecking engineers and field crew performed a detailed bridge inspection to ensure the demo sequence

planned would work. Metro-North Railroad approved the plan and the project moved forward with a requirement to finish the job in 90 days.

Shored Up, Seamless Execution

The Sessler Wrecking demolition plan called for a combination of engineered shoring system technology which was light enough to be primarily set by hand, excavators and skid steers

which could not have a combined weight of over 50,000 lbs and steel removal utilizing a 250-ton, all-terrain hydraulic crane.

The deck removal progressed from south to north. Each deck section was saw cut in pieces not exceeding 9,000 lbs (away from the railroad tracks) and 6,000 lbs (when working within 15 ft of the railroad tracks), removed with the excavator, and then the concrete deck pieces were slid the length of the bridge with a skid steer.

Once off the deck, a larger excavator processed the slabs on site, removing the reinforcing for recycling and preparing the concrete for further processing with an onsite concrete crushing plant. The remaining downsized material was fed through the crusher to be downsized to 5-in. minus for beneficial reuse on site.

Once the concrete had been removed, the demolition procedure required over 70 crane picks to be performed from three separate locations. Each pick was part of a sequence which began at the south end of the structure and finished at the north end. Many of the picks encroached on the 15-ft foul zone of the railroad tracks which, like the concrete deck removal,

had to be completed in the early morning hours.

As is typical with Sessler Wrecking projects, a strong focus on environmental sustainability was a factor, as all the demolition materials were either processed and reused on site or sent off site for recycling.

“Working in close coordination with our partners at Sleepy Hollow Local Development Corp. and Metro-North Railroad was key to the success of the project. With detailed planning and

excellent execution in the field, we were able to complete the demolition ahead of schedule,” says Todd Worden, general superintendent of Bridge Demolition at Sessler Wrecking. “We

have a great team of skilled and dedicated laborers, operators, truck drivers and superintendents that tackled this project with the precision and professionalism that Sessler Wrecking is best known for.”